What excellent corrosion resistance does the ceramic plunger show in harsh environments?

Release Time : 2025-06-30

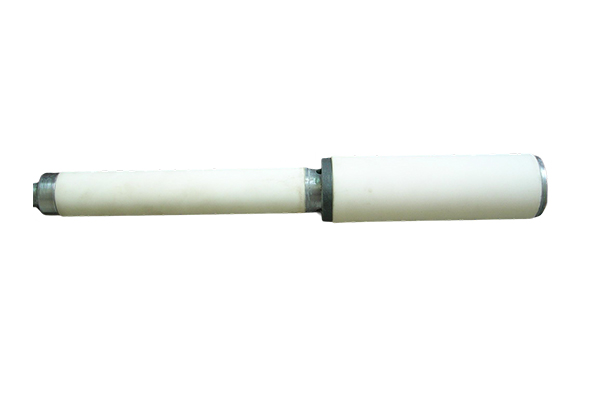

In harsh environments, ceramic plungers show excellent corrosion resistance, which not only enhances the reliability of the equipment, but also extends its service life, providing efficient and durable solutions for many industries. Ceramic plungers, with their unique material properties, have shown excellent corrosion resistance in the face of various chemicals and extreme environments, and have become an indispensable part of many critical applications.

First of all, the main components of ceramic plungers determine their excellent corrosion resistance. Ceramic materials are usually composed of high-purity inorganic compounds such as alumina and zirconium oxide, which have extremely high chemical stability and are not easy to react with acid and alkali solutions. Therefore, when ceramic plungers are used in environments containing strong acid or alkali media, they can effectively resist the erosion of these corrosive substances, keeping the surface smooth and the structure intact. This is especially important for pumping systems commonly used in the chemical industry, because these systems often need to handle a variety of highly corrosive chemicals. Using ceramic plungers can avoid the common corrosion problems of metal plungers and ensure the long-term stable operation of the system.

Secondly, the corrosion resistance of ceramic plungers under high temperature conditions is also remarkable. Many industrial processes not only involve corrosive media, but also need to operate at high temperatures. In this case, traditional metal materials often fail due to accelerated corrosion at high temperatures. However, ceramic materials can maintain excellent chemical inertness in high temperature environments due to their special crystal structure and chemical bonding method. This means that even if they are exposed to corrosive liquids for a long time under high temperature conditions, ceramic plungers will not age or be damaged significantly. This feature makes ceramic plungers particularly widely used in industries such as petroleum refining and metallurgy because they can cope with the challenges brought by high temperature and high pressure environments.

Furthermore, ceramic plungers have good wear resistance, which is also an important part of their corrosion resistance. In practical applications, in addition to chemical corrosion, mechanical wear is also a factor that cannot be ignored. Especially in the process of conveying fluids containing solid particles, the impact and friction of particles on the plunger surface will cause severe wear, which in turn causes local corrosion. Ceramic materials have extremely high hardness and smooth surface, which can effectively resist the wear of particles and reduce the risk of corrosion caused by wear. At the same time, the low friction coefficient of ceramic plungers also helps to reduce running resistance, further reducing the degree of wear. This feature makes the ceramic plunger perform well in the slurry delivery system of the mining, papermaking and other industries, ensuring the efficient operation of the system.

Not only that, the ceramic plunger also exhibits excellent anti-penetration performance. Some corrosive media will not only directly erode the surface of the material, but also try to penetrate into the material through tiny pores or cracks, causing deep corrosion. However, the density and uniformity of ceramic materials make it almost non-existent with such microscopic defects, thus effectively preventing the penetration of corrosive substances. In addition, some specially formulated ceramic materials also have self-healing functions, that is, when there is a small damage on the surface, the material can self-repair to a certain extent and maintain its original protective effect. This is crucial for those application scenarios that require extremely high sealing, such as precision equipment in the food processing and pharmaceutical industries.

In addition, the application of ceramic plungers also improves the safety and environmental performance of the overall system. Due to its excellent corrosion resistance, ceramic plungers reduce the risk of leakage caused by corrosion, avoid the leakage of harmful substances into the environment, and protect the ecological environment. At the same time, this also means that operators do not have to frequently replace damaged parts, reducing maintenance frequency and costs, and improving work efficiency. For production lines that need to run continuously and uninterruptedly, choosing a ceramic plunger is undoubtedly a wise move, because it ensures the continuity and stability of production.

It is worth mentioning that with the advancement of technology, modern ceramic plungers have also made significant progress in manufacturing processes. Advanced sintering technology and precision machining methods make the quality of ceramic plungers more reliable and the dimensional accuracy higher. This not only meets the strict requirements of different application scenarios on the shape and size of the plunger, but also brings users a better installation experience. Customized ceramic plungers can be designed and manufactured according to specific needs, taking into full account various factors in the actual working environment, such as temperature changes, pressure fluctuations, and medium characteristics, so as to maximize its corrosion resistance advantages.

Finally, in practical applications, ceramic plungers have been widely used due to their excellent corrosion resistance. Whether it is a high-pressure pumping system in the petrochemical field, a seawater treatment device in marine engineering, or a precision syringe in medical equipment, ceramic plungers have shown incomparable advantages. It can not only cope with complex working conditions, but also provide long-lasting and reliable performance guarantees. For users who pursue high quality and high performance, ceramic plungers are undoubtedly one of the best choices.

In summary, in harsh environments, ceramic plungers show excellent corrosion resistance. From basic chemical stability to complex mechanical wear and microscopic penetration protection, every detail provides users with a more reliable, efficient and environmentally friendly product. With the development of science and technology and the advancement of technology, the future ceramic plunger will continue to take solid steps in improving equipment performance, optimizing production processes, and bringing more innovative solutions to various industries. In this process, continuous attention to user needs and technological innovation will be the key driving force for product development.

First of all, the main components of ceramic plungers determine their excellent corrosion resistance. Ceramic materials are usually composed of high-purity inorganic compounds such as alumina and zirconium oxide, which have extremely high chemical stability and are not easy to react with acid and alkali solutions. Therefore, when ceramic plungers are used in environments containing strong acid or alkali media, they can effectively resist the erosion of these corrosive substances, keeping the surface smooth and the structure intact. This is especially important for pumping systems commonly used in the chemical industry, because these systems often need to handle a variety of highly corrosive chemicals. Using ceramic plungers can avoid the common corrosion problems of metal plungers and ensure the long-term stable operation of the system.

Secondly, the corrosion resistance of ceramic plungers under high temperature conditions is also remarkable. Many industrial processes not only involve corrosive media, but also need to operate at high temperatures. In this case, traditional metal materials often fail due to accelerated corrosion at high temperatures. However, ceramic materials can maintain excellent chemical inertness in high temperature environments due to their special crystal structure and chemical bonding method. This means that even if they are exposed to corrosive liquids for a long time under high temperature conditions, ceramic plungers will not age or be damaged significantly. This feature makes ceramic plungers particularly widely used in industries such as petroleum refining and metallurgy because they can cope with the challenges brought by high temperature and high pressure environments.

Furthermore, ceramic plungers have good wear resistance, which is also an important part of their corrosion resistance. In practical applications, in addition to chemical corrosion, mechanical wear is also a factor that cannot be ignored. Especially in the process of conveying fluids containing solid particles, the impact and friction of particles on the plunger surface will cause severe wear, which in turn causes local corrosion. Ceramic materials have extremely high hardness and smooth surface, which can effectively resist the wear of particles and reduce the risk of corrosion caused by wear. At the same time, the low friction coefficient of ceramic plungers also helps to reduce running resistance, further reducing the degree of wear. This feature makes the ceramic plunger perform well in the slurry delivery system of the mining, papermaking and other industries, ensuring the efficient operation of the system.

Not only that, the ceramic plunger also exhibits excellent anti-penetration performance. Some corrosive media will not only directly erode the surface of the material, but also try to penetrate into the material through tiny pores or cracks, causing deep corrosion. However, the density and uniformity of ceramic materials make it almost non-existent with such microscopic defects, thus effectively preventing the penetration of corrosive substances. In addition, some specially formulated ceramic materials also have self-healing functions, that is, when there is a small damage on the surface, the material can self-repair to a certain extent and maintain its original protective effect. This is crucial for those application scenarios that require extremely high sealing, such as precision equipment in the food processing and pharmaceutical industries.

In addition, the application of ceramic plungers also improves the safety and environmental performance of the overall system. Due to its excellent corrosion resistance, ceramic plungers reduce the risk of leakage caused by corrosion, avoid the leakage of harmful substances into the environment, and protect the ecological environment. At the same time, this also means that operators do not have to frequently replace damaged parts, reducing maintenance frequency and costs, and improving work efficiency. For production lines that need to run continuously and uninterruptedly, choosing a ceramic plunger is undoubtedly a wise move, because it ensures the continuity and stability of production.

It is worth mentioning that with the advancement of technology, modern ceramic plungers have also made significant progress in manufacturing processes. Advanced sintering technology and precision machining methods make the quality of ceramic plungers more reliable and the dimensional accuracy higher. This not only meets the strict requirements of different application scenarios on the shape and size of the plunger, but also brings users a better installation experience. Customized ceramic plungers can be designed and manufactured according to specific needs, taking into full account various factors in the actual working environment, such as temperature changes, pressure fluctuations, and medium characteristics, so as to maximize its corrosion resistance advantages.

Finally, in practical applications, ceramic plungers have been widely used due to their excellent corrosion resistance. Whether it is a high-pressure pumping system in the petrochemical field, a seawater treatment device in marine engineering, or a precision syringe in medical equipment, ceramic plungers have shown incomparable advantages. It can not only cope with complex working conditions, but also provide long-lasting and reliable performance guarantees. For users who pursue high quality and high performance, ceramic plungers are undoubtedly one of the best choices.

In summary, in harsh environments, ceramic plungers show excellent corrosion resistance. From basic chemical stability to complex mechanical wear and microscopic penetration protection, every detail provides users with a more reliable, efficient and environmentally friendly product. With the development of science and technology and the advancement of technology, the future ceramic plunger will continue to take solid steps in improving equipment performance, optimizing production processes, and bringing more innovative solutions to various industries. In this process, continuous attention to user needs and technological innovation will be the key driving force for product development.