How to improve the thermal conductivity of the heat dissipation substrate to achieve more efficient heat dissipation?

Release Time : 2025-06-16

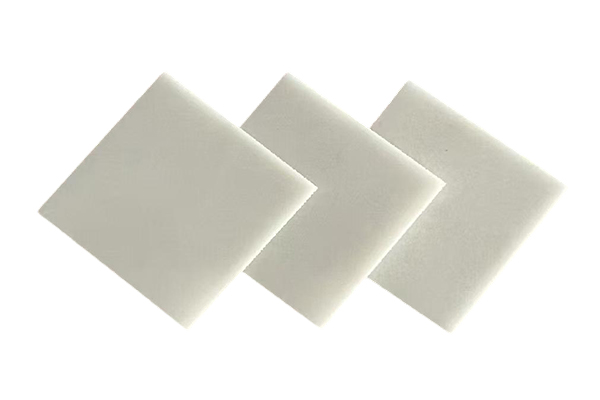

Aluminum nitride substrate plays a vital role in modern electronic devices, especially in heat dissipation management. As a heat dissipation substrate material, aluminum nitride provides a more efficient heat dissipation solution for electronic components with its excellent thermal conductivity and other excellent properties, ensuring the stable operation and extended service life of the equipment.

The reason why aluminum nitride substrate can significantly improve the heat dissipation efficiency is firstly due to its unique crystal structure and composition. Aluminum nitride is a ceramic material with high thermal conductivity. The strong covalent bonding between its atoms gives it excellent thermal conductivity. This means that heat can be quickly transferred from high temperature areas to low temperature areas, effectively avoiding the occurrence of local overheating. For electronic components that require efficient heat dissipation to maintain normal operation, such as power devices, LEDs, etc., the use of aluminum nitride substrate can greatly reduce the risk of failure caused by excessive temperature.

In addition to its inherent high thermal conductivity, aluminum nitride substrate also has good mechanical strength and dimensional stability. This makes it less likely to deform or damage during the manufacturing process, thereby ensuring the quality consistency of the final product. In practical applications, this stability means that even when working for long periods of time or experiencing drastic temperature changes, the aluminum nitride substrate can maintain its original thermal conductivity and continue to effectively transfer heat away from key components. This is particularly important for devices that need to operate reliably for a long time in harsh environments.

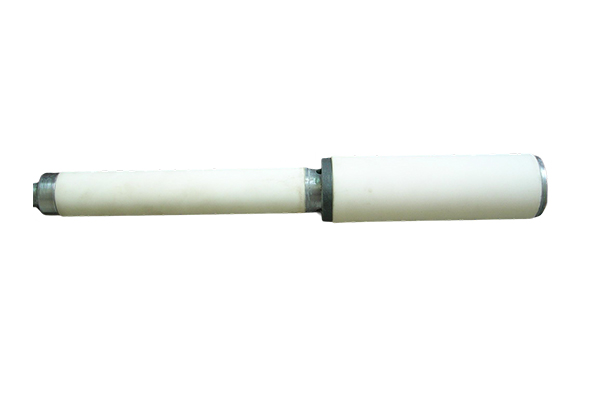

Another major advantage of aluminum nitride substrate is its electrical insulation. Despite its extremely high thermal conductivity, aluminum nitride itself is an electrical insulator, which makes it very suitable for applications that require both electrical isolation and efficient heat dissipation. For example, in the field of semiconductor packaging, aluminum nitride substrate can not only effectively dissipate the heat generated by the chip, but also ensure electrical isolation between different circuits to prevent short circuits or other electrical failures. Such a dual protection mechanism not only improves the safety of the system, but also enhances the overall performance.

In addition, aluminum nitride substrate performs well in chemical corrosion resistance. Although many traditional metal materials have good thermal conductivity, they are easily corroded in acidic and alkaline environments, which affects their thermal conductivity and even causes failure. Aluminum nitride, due to its stable chemical properties, can maintain stable physical and chemical properties in a variety of corrosive environments, ensuring the reliability of the heat dissipation system throughout its life cycle. This is undoubtedly a huge advantage for the chemical industry or occasions involving special media processing.

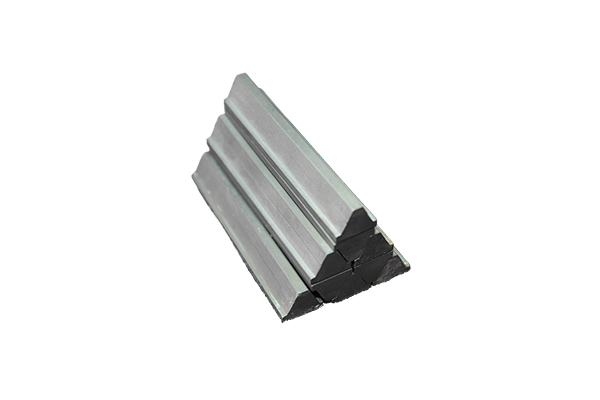

Not only that, the surface treatment technology of aluminum nitride substrate is also constantly improving, further optimizing its thermal conductivity. Through a specific surface treatment process, the tiny defects and flatness problems on the substrate surface can be reduced, thereby reducing thermal resistance and making heat transfer smoother. This refined processing not only improves the thermal conductivity of the aluminum nitride substrate itself, but also provides a better basic condition for thermal management in the subsequent assembly and integration process.

Finally, the design flexibility of aluminum nitride substrate is also a major feature. According to the requirements of different application scenarios, the most suitable heat dissipation solution can be customized by adjusting the thickness, shape, and adding other functional layers. Whether it is an ultra-thin design to meet the needs of portable devices, or a reinforced structure to cope with high-power conditions, aluminum nitride substrate can provide a variety of options to help engineers achieve the best heat dissipation effect.

In summary, aluminum nitride substrate has demonstrated unparalleled advantages in improving the thermal conductivity of heat dissipation substrates through its high thermal conductivity, excellent mechanical properties, electrical insulation, chemical corrosion resistance, and flexible design options. These features work together to make aluminum nitride substrate one of the ideal materials for solving the heat dissipation problems of modern electronic devices, and promote technological innovation and development in multiple industries including semiconductors and LED lighting. With the advancement of technology, aluminum nitride substrate is expected to play a greater role in more fields in the future, bringing more advanced and reliable heat dissipation solutions to all walks of life.

The reason why aluminum nitride substrate can significantly improve the heat dissipation efficiency is firstly due to its unique crystal structure and composition. Aluminum nitride is a ceramic material with high thermal conductivity. The strong covalent bonding between its atoms gives it excellent thermal conductivity. This means that heat can be quickly transferred from high temperature areas to low temperature areas, effectively avoiding the occurrence of local overheating. For electronic components that require efficient heat dissipation to maintain normal operation, such as power devices, LEDs, etc., the use of aluminum nitride substrate can greatly reduce the risk of failure caused by excessive temperature.

In addition to its inherent high thermal conductivity, aluminum nitride substrate also has good mechanical strength and dimensional stability. This makes it less likely to deform or damage during the manufacturing process, thereby ensuring the quality consistency of the final product. In practical applications, this stability means that even when working for long periods of time or experiencing drastic temperature changes, the aluminum nitride substrate can maintain its original thermal conductivity and continue to effectively transfer heat away from key components. This is particularly important for devices that need to operate reliably for a long time in harsh environments.

Another major advantage of aluminum nitride substrate is its electrical insulation. Despite its extremely high thermal conductivity, aluminum nitride itself is an electrical insulator, which makes it very suitable for applications that require both electrical isolation and efficient heat dissipation. For example, in the field of semiconductor packaging, aluminum nitride substrate can not only effectively dissipate the heat generated by the chip, but also ensure electrical isolation between different circuits to prevent short circuits or other electrical failures. Such a dual protection mechanism not only improves the safety of the system, but also enhances the overall performance.

In addition, aluminum nitride substrate performs well in chemical corrosion resistance. Although many traditional metal materials have good thermal conductivity, they are easily corroded in acidic and alkaline environments, which affects their thermal conductivity and even causes failure. Aluminum nitride, due to its stable chemical properties, can maintain stable physical and chemical properties in a variety of corrosive environments, ensuring the reliability of the heat dissipation system throughout its life cycle. This is undoubtedly a huge advantage for the chemical industry or occasions involving special media processing.

Not only that, the surface treatment technology of aluminum nitride substrate is also constantly improving, further optimizing its thermal conductivity. Through a specific surface treatment process, the tiny defects and flatness problems on the substrate surface can be reduced, thereby reducing thermal resistance and making heat transfer smoother. This refined processing not only improves the thermal conductivity of the aluminum nitride substrate itself, but also provides a better basic condition for thermal management in the subsequent assembly and integration process.

Finally, the design flexibility of aluminum nitride substrate is also a major feature. According to the requirements of different application scenarios, the most suitable heat dissipation solution can be customized by adjusting the thickness, shape, and adding other functional layers. Whether it is an ultra-thin design to meet the needs of portable devices, or a reinforced structure to cope with high-power conditions, aluminum nitride substrate can provide a variety of options to help engineers achieve the best heat dissipation effect.

In summary, aluminum nitride substrate has demonstrated unparalleled advantages in improving the thermal conductivity of heat dissipation substrates through its high thermal conductivity, excellent mechanical properties, electrical insulation, chemical corrosion resistance, and flexible design options. These features work together to make aluminum nitride substrate one of the ideal materials for solving the heat dissipation problems of modern electronic devices, and promote technological innovation and development in multiple industries including semiconductors and LED lighting. With the advancement of technology, aluminum nitride substrate is expected to play a greater role in more fields in the future, bringing more advanced and reliable heat dissipation solutions to all walks of life.