Why is WC Tungsten Carbide an ideal material for many industrial applications?

Release Time : 2025-06-03

In the modern industrial field, it is always a challenge to find a material that can withstand extreme environmental conditions and provide excellent performance. As a non-metallic material with insulation, corrosion resistance and high temperature resistance, WC Tungsten Carbide is widely used in many industries due to its unique physical and chemical properties. So, what unique advantages does this high-performance material have that make it stand out in many application scenarios?

First of all, WC Tungsten Carbide is known for its excellent high temperature resistance. This material can maintain structural stability and mechanical strength at extremely high temperatures, and can work normally without softening or deformation even in an environment exceeding 1000 degrees Celsius. This makes it an ideal choice for manufacturing high-temperature furnaces, cutting tools, and aerospace engine components. For example, in the steel smelting process, thermocouple protection tubes made of WC Tungsten Carbide can resist the erosion of molten metal and ensure the accuracy of temperature measurement; and in high temperature and high pressure environments such as rocket nozzles, its excellent heat resistance has also been widely used.

Secondly, wc tungsten carbide exhibits excellent corrosion resistance. Whether facing strong acids, strong alkalis or other corrosive media, the material can effectively resist erosion and maintain surface integrity and functionality. This feature is particularly important for key components such as pipes, valves and reactor linings in the chemical industry. By using wc tungsten carbide as an anti-corrosion layer or directly preparing it into related components, the service life of the equipment can be significantly extended, maintenance costs can be reduced, and production safety can be improved.

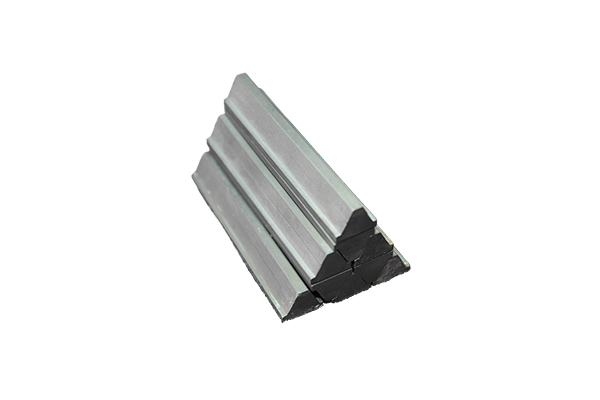

Furthermore, although it is classified as a non-metallic material, wc tungsten carbide has excellent hardness and wear resistance. Its hardness is second only to diamond, so it is often used to make knives, drills and other cutting tools. These tools not only perform well in processing cemented carbide, but also can cope with efficient cutting operations of high-strength steel, greatly improving work efficiency and product quality. In addition, in the fields of mining, geological exploration, etc., drilling tools made of wc tungsten carbide are also favored for their durability.

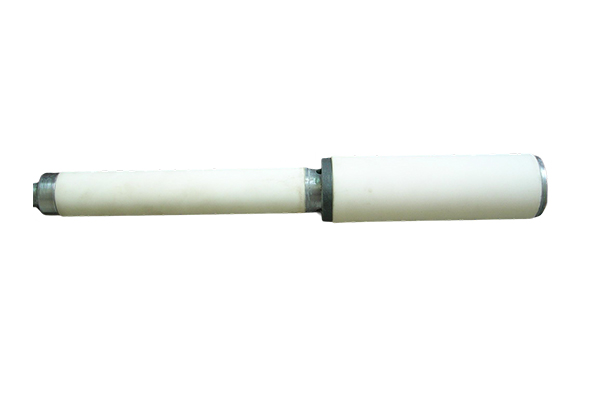

It is worth noting that although WC tungsten carbide has good electrical conductivity, it can also be used as an insulating material under certain conditions. This is mainly due to the precise control of its microstructure and composition ratio. When it is necessary to meet both mechanical support and insulation requirements in an electrical system, such as the disconnector bracket in a high-voltage switch cabinet, WC tungsten carbide becomes one of the preferred materials due to its unique comprehensive performance.

In addition, with the enhancement of environmental awareness and the advancement of technology, the application scope of WC tungsten carbide is still expanding. For example, in the field of new energy, components such as solar panel frames and wind turbine blade root connectors have also begun to try to use this material to take advantage of its lightweight, high strength and fatigue resistance to further improve the overall efficiency of the equipment.

Finally, WC tungsten carbide also has a certain degree of biocompatibility, which means that it also has potential application prospects in medical implants. Although this application is still in the research stage, studies have shown that specially treated WC tungsten carbide can be used to manufacture medical devices such as artificial joints and dental restorations, which is expected to improve the quality of life of patients.

In summary, wc tungsten carbide has become one of the core materials in many industrial fields due to its multiple advantages such as high temperature resistance, corrosion resistance, high hardness and multifunctional application potential. Whether it is tool manufacturing in traditional manufacturing, green energy development in emerging fields, or future medical technology innovation, this material has shown great development potential. With the continuous development of science and technology, we have reason to believe that wc tungsten carbide will continue to promote the progress of various industries and open up more possibilities.

First of all, WC Tungsten Carbide is known for its excellent high temperature resistance. This material can maintain structural stability and mechanical strength at extremely high temperatures, and can work normally without softening or deformation even in an environment exceeding 1000 degrees Celsius. This makes it an ideal choice for manufacturing high-temperature furnaces, cutting tools, and aerospace engine components. For example, in the steel smelting process, thermocouple protection tubes made of WC Tungsten Carbide can resist the erosion of molten metal and ensure the accuracy of temperature measurement; and in high temperature and high pressure environments such as rocket nozzles, its excellent heat resistance has also been widely used.

Secondly, wc tungsten carbide exhibits excellent corrosion resistance. Whether facing strong acids, strong alkalis or other corrosive media, the material can effectively resist erosion and maintain surface integrity and functionality. This feature is particularly important for key components such as pipes, valves and reactor linings in the chemical industry. By using wc tungsten carbide as an anti-corrosion layer or directly preparing it into related components, the service life of the equipment can be significantly extended, maintenance costs can be reduced, and production safety can be improved.

Furthermore, although it is classified as a non-metallic material, wc tungsten carbide has excellent hardness and wear resistance. Its hardness is second only to diamond, so it is often used to make knives, drills and other cutting tools. These tools not only perform well in processing cemented carbide, but also can cope with efficient cutting operations of high-strength steel, greatly improving work efficiency and product quality. In addition, in the fields of mining, geological exploration, etc., drilling tools made of wc tungsten carbide are also favored for their durability.

It is worth noting that although WC tungsten carbide has good electrical conductivity, it can also be used as an insulating material under certain conditions. This is mainly due to the precise control of its microstructure and composition ratio. When it is necessary to meet both mechanical support and insulation requirements in an electrical system, such as the disconnector bracket in a high-voltage switch cabinet, WC tungsten carbide becomes one of the preferred materials due to its unique comprehensive performance.

In addition, with the enhancement of environmental awareness and the advancement of technology, the application scope of WC tungsten carbide is still expanding. For example, in the field of new energy, components such as solar panel frames and wind turbine blade root connectors have also begun to try to use this material to take advantage of its lightweight, high strength and fatigue resistance to further improve the overall efficiency of the equipment.

Finally, WC tungsten carbide also has a certain degree of biocompatibility, which means that it also has potential application prospects in medical implants. Although this application is still in the research stage, studies have shown that specially treated WC tungsten carbide can be used to manufacture medical devices such as artificial joints and dental restorations, which is expected to improve the quality of life of patients.

In summary, wc tungsten carbide has become one of the core materials in many industrial fields due to its multiple advantages such as high temperature resistance, corrosion resistance, high hardness and multifunctional application potential. Whether it is tool manufacturing in traditional manufacturing, green energy development in emerging fields, or future medical technology innovation, this material has shown great development potential. With the continuous development of science and technology, we have reason to believe that wc tungsten carbide will continue to promote the progress of various industries and open up more possibilities.