How does a vacuum injection tube achieve efficient insulation?

Release Time : 2025-05-19

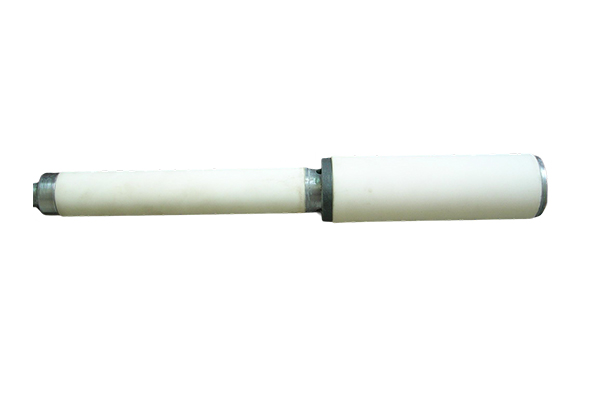

In modern industry and technology, vacuum injection technology is widely used in many high-end industries such as semiconductor manufacturing, medical devices, aerospace, and high-precision electronic equipment. As a key component in this system, the vacuum injection tube not only needs to have good sealing and pressure resistance, but also has extremely high requirements for electrical insulation performance. Especially in high-voltage or high-frequency environments, the insulation capacity of the vacuum injection tube is directly related to the operating safety and stability of the entire system.

Material selection: the core factor that determines insulation performance

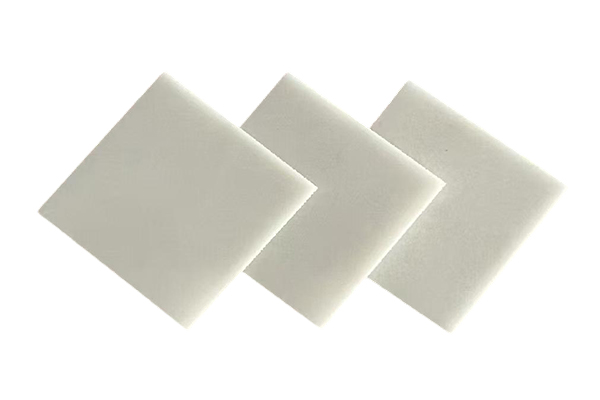

For a vacuum injection tube to achieve efficient insulation, the first thing is that the material used must have excellent electrical insulation. The current mainstream non-metallic materials include high-performance engineering plastics such as polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), and polyimide (PI). These materials have extremely low dielectric constants and high volume resistivity, and can remain stable under extreme voltages without breakdown or leakage current. For example,, which can almost be regarded as an ideal insulator. In addition, this type of material also has good high temperature resistance and corrosion resistance, so that it can still maintain excellent insulation performance under complex working conditions.

Structural design: reduce electric field concentration and improve overall safety

In addition to the superiority of the material itself, the structural design of the vacuum injection tube also directly affects its insulation effect. In order to prevent local discharge or even breakdown caused by electric field concentration, engineers usually use rounded transition design, gradient shielding structure and other methods to optimize the electric field distribution. For example, in high-voltage applications, by setting a conductive layer or semi-conductive layer on the inner and outer surfaces of the tube body, the charge flow can be effectively guided to avoid static electricity accumulation. At the same time, some high-end products will also adopt a multi-layer composite structure to organically combine different functional layers (such as conductive layer, insulating layer, protective layer) to achieve multiple insulation protection, thereby greatly improving the overall electrical safety.

Process control: ensure the maximum performance of material performance

The manufacturing process of the vacuum injection tube has a decisive influence on its final insulation performance. Especially in the molding and post-processing stages, any tiny bubbles, impurities or cracks may become a hidden danger of electrical breakdown. Therefore, advanced vacuum injection molding technology is widely used. By eliminating air interference in a closed environment, the material can be ensured to fill the mold evenly and densely, thereby obtaining a defect-free finished product. In addition, post-processing steps such as heat treatment and surface polishing can further improve the density and surface smoothness of the material, reduce the risk of electric field distortion caused by surface roughness, and enhance the insulation stability under long-term use.

Insulation performance in practical applications

In practical applications, the insulation performance of vacuum injection tubes often faces severe tests. For example, in the semiconductor manufacturing process, high-pressure gas injection in a vacuum environment requires the pipeline to have the ability to resist arc and aging for a long time; while in medical equipment, vacuum injection tubes need to maintain a stable insulation state under humid, high-temperature or frequent disinfection conditions. Thanks to the comprehensive optimization of the above materials, structures and processes, vacuum injection tubes can still perform well in these harsh environments. Experimental data show that the breakdown voltage of vacuum injection tubes made of high-performance insulating materials and precision-processed can reach more than 30kV/mm, far exceeding ordinary plastic products, and fully meeting industrial and even military standards.

In summary, the high-efficiency insulation of vacuum injection tubes is inseparable from the progress of material science, the optimization of structural design, and the support of advanced manufacturing processes. From material selection to molding to the adaptation of application scenarios, every link serves the core goal of "insulation". With the continuous development of industrial automation and high-end manufacturing, the demand for the insulation performance of vacuum injection tubes will continue to upgrade, and the iteration of related technologies and products will also provide a more solid technical guarantee for it.

Material selection: the core factor that determines insulation performance

For a vacuum injection tube to achieve efficient insulation, the first thing is that the material used must have excellent electrical insulation. The current mainstream non-metallic materials include high-performance engineering plastics such as polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), and polyimide (PI). These materials have extremely low dielectric constants and high volume resistivity, and can remain stable under extreme voltages without breakdown or leakage current. For example,, which can almost be regarded as an ideal insulator. In addition, this type of material also has good high temperature resistance and corrosion resistance, so that it can still maintain excellent insulation performance under complex working conditions.

Structural design: reduce electric field concentration and improve overall safety

In addition to the superiority of the material itself, the structural design of the vacuum injection tube also directly affects its insulation effect. In order to prevent local discharge or even breakdown caused by electric field concentration, engineers usually use rounded transition design, gradient shielding structure and other methods to optimize the electric field distribution. For example, in high-voltage applications, by setting a conductive layer or semi-conductive layer on the inner and outer surfaces of the tube body, the charge flow can be effectively guided to avoid static electricity accumulation. At the same time, some high-end products will also adopt a multi-layer composite structure to organically combine different functional layers (such as conductive layer, insulating layer, protective layer) to achieve multiple insulation protection, thereby greatly improving the overall electrical safety.

Process control: ensure the maximum performance of material performance

The manufacturing process of the vacuum injection tube has a decisive influence on its final insulation performance. Especially in the molding and post-processing stages, any tiny bubbles, impurities or cracks may become a hidden danger of electrical breakdown. Therefore, advanced vacuum injection molding technology is widely used. By eliminating air interference in a closed environment, the material can be ensured to fill the mold evenly and densely, thereby obtaining a defect-free finished product. In addition, post-processing steps such as heat treatment and surface polishing can further improve the density and surface smoothness of the material, reduce the risk of electric field distortion caused by surface roughness, and enhance the insulation stability under long-term use.

Insulation performance in practical applications

In practical applications, the insulation performance of vacuum injection tubes often faces severe tests. For example, in the semiconductor manufacturing process, high-pressure gas injection in a vacuum environment requires the pipeline to have the ability to resist arc and aging for a long time; while in medical equipment, vacuum injection tubes need to maintain a stable insulation state under humid, high-temperature or frequent disinfection conditions. Thanks to the comprehensive optimization of the above materials, structures and processes, vacuum injection tubes can still perform well in these harsh environments. Experimental data show that the breakdown voltage of vacuum injection tubes made of high-performance insulating materials and precision-processed can reach more than 30kV/mm, far exceeding ordinary plastic products, and fully meeting industrial and even military standards.

In summary, the high-efficiency insulation of vacuum injection tubes is inseparable from the progress of material science, the optimization of structural design, and the support of advanced manufacturing processes. From material selection to molding to the adaptation of application scenarios, every link serves the core goal of "insulation". With the continuous development of industrial automation and high-end manufacturing, the demand for the insulation performance of vacuum injection tubes will continue to upgrade, and the iteration of related technologies and products will also provide a more solid technical guarantee for it.