How to use aluminum nitride substrate to improve the heat dissipation performance of electronic devices?

Release Time : 2025-07-14

In modern electronic devices, with the continuous improvement of integration and power density, heat dissipation has become one of the key factors restricting performance and reliability. Traditional heat dissipation solutions often fail to meet the needs of high-power devices, while aluminum nitride substrate has shown unique advantages in improving the heat dissipation performance of electronic devices with its excellent thermal conductivity and excellent mechanical properties.

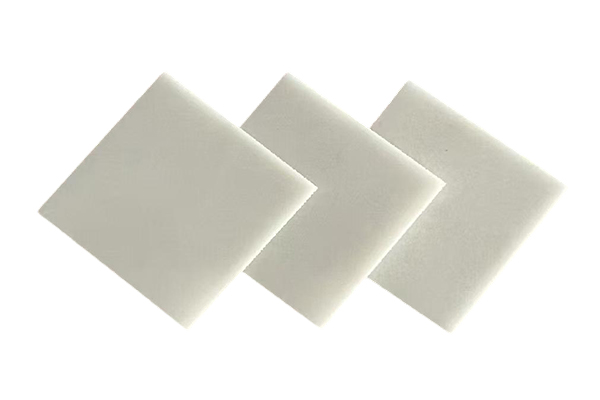

As a type of ceramic substrate, aluminum nitride substrate stands out for its excellent thermal conductivity. This material can quickly conduct heat away from the heat source, effectively avoiding the occurrence of local overheating. For electronic components that need to process a lot of information or generate high heat, the use of aluminum nitride substrate can significantly reduce the operating temperature, thereby improving overall operating efficiency and extending service life. Due to the high thermal conductivity of aluminum nitride substrate, it can effectively distribute heat evenly over the entire substrate surface, and further accelerate the heat dissipation process by combining with external heat dissipation devices (such as heat sinks or cooling systems).

In addition to its efficient thermal conductivity, aluminum nitride substrate also has good mechanical strength and stability, which enables it to maintain structural integrity and functional effectiveness under extreme conditions. For example, when working for a long time in a high temperature environment, the aluminum nitride substrate will not deform or be damaged, ensuring the long-term stable operation of electronic equipment. In addition, this substrate material has strong adaptability to environmental changes, and can maintain stable performance regardless of humidity, chemicals or mechanical stress. Therefore, the use of aluminum nitride substrate not only helps to solve the heat dissipation problem, but also enhances the anti-interference ability and reliability of the entire system.

Aluminum nitride substrate also provides great flexibility in design. It can be made into various shapes and sizes to meet the needs of different types of electronic components. This means that engineers can optimize the design of the substrate according to the specific application scenario, maximize the use of space and achieve the best heat dissipation effect. At the same time, the surface of aluminum nitride substrate is smooth and flat, easy to weld or bond with other materials, and easy to install and maintain. These characteristics make aluminum nitride substrate very suitable for high-density packaging and complex circuit layout, providing strong support for the miniaturization and integration of electronic equipment.

It is worth noting that the aluminum nitride substrate also has excellent electrical insulation properties, which simplifies the circuit design to a certain extent. Since the substrate itself is not conductive, conductive lines can be arranged directly on its surface without adding an additional insulating layer. This not only saves costs, but also reduces the problem of increased thermal resistance caused by the multi-layer structure, further improving the heat dissipation efficiency. In addition, the low dielectric constant of the aluminum nitride substrate is also conducive to high-frequency signal transmission, reducing signal loss and delay, and is particularly suitable for high-speed communication and radio frequency applications.

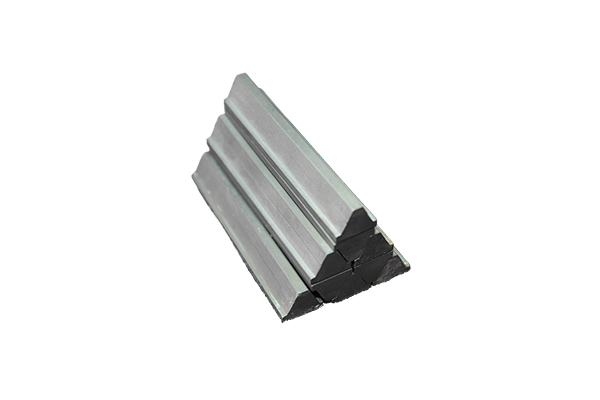

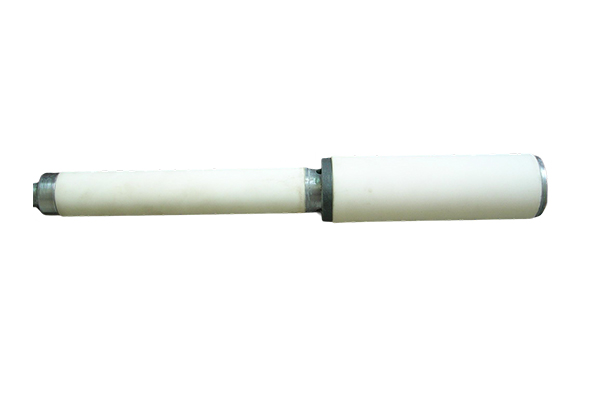

In practical applications, aluminum nitride substrate is often combined with other heat dissipation technologies to form a comprehensive heat dissipation solution. For example, it can be used in conjunction with a metal heat sink to quickly transfer heat through direct contact; it can also be used in conjunction with a liquid cooling system to take away more heat with the help of the powerful heat exchange capacity of the liquid medium. These combinations give full play to their respective advantages and achieve more efficient and reliable heat dissipation effects.

In general, aluminum nitride substrate has great potential in improving the heat dissipation performance of electronic devices with its excellent thermal conductivity, mechanical strength and design flexibility. It can not only effectively reduce the operating temperature of electronic components and improve work efficiency, but also enhance the stability and durability of the system. With the advancement of technology and the growth of market demand, aluminum nitride substrate will be widely used in more fields and make greater contributions to promoting the innovative development of the electronics industry. In the future, we can expect to see more innovative designs based on aluminum nitride substrate, providing a more comprehensive and effective solution to the heat dissipation problem.

As a type of ceramic substrate, aluminum nitride substrate stands out for its excellent thermal conductivity. This material can quickly conduct heat away from the heat source, effectively avoiding the occurrence of local overheating. For electronic components that need to process a lot of information or generate high heat, the use of aluminum nitride substrate can significantly reduce the operating temperature, thereby improving overall operating efficiency and extending service life. Due to the high thermal conductivity of aluminum nitride substrate, it can effectively distribute heat evenly over the entire substrate surface, and further accelerate the heat dissipation process by combining with external heat dissipation devices (such as heat sinks or cooling systems).

In addition to its efficient thermal conductivity, aluminum nitride substrate also has good mechanical strength and stability, which enables it to maintain structural integrity and functional effectiveness under extreme conditions. For example, when working for a long time in a high temperature environment, the aluminum nitride substrate will not deform or be damaged, ensuring the long-term stable operation of electronic equipment. In addition, this substrate material has strong adaptability to environmental changes, and can maintain stable performance regardless of humidity, chemicals or mechanical stress. Therefore, the use of aluminum nitride substrate not only helps to solve the heat dissipation problem, but also enhances the anti-interference ability and reliability of the entire system.

Aluminum nitride substrate also provides great flexibility in design. It can be made into various shapes and sizes to meet the needs of different types of electronic components. This means that engineers can optimize the design of the substrate according to the specific application scenario, maximize the use of space and achieve the best heat dissipation effect. At the same time, the surface of aluminum nitride substrate is smooth and flat, easy to weld or bond with other materials, and easy to install and maintain. These characteristics make aluminum nitride substrate very suitable for high-density packaging and complex circuit layout, providing strong support for the miniaturization and integration of electronic equipment.

It is worth noting that the aluminum nitride substrate also has excellent electrical insulation properties, which simplifies the circuit design to a certain extent. Since the substrate itself is not conductive, conductive lines can be arranged directly on its surface without adding an additional insulating layer. This not only saves costs, but also reduces the problem of increased thermal resistance caused by the multi-layer structure, further improving the heat dissipation efficiency. In addition, the low dielectric constant of the aluminum nitride substrate is also conducive to high-frequency signal transmission, reducing signal loss and delay, and is particularly suitable for high-speed communication and radio frequency applications.

In practical applications, aluminum nitride substrate is often combined with other heat dissipation technologies to form a comprehensive heat dissipation solution. For example, it can be used in conjunction with a metal heat sink to quickly transfer heat through direct contact; it can also be used in conjunction with a liquid cooling system to take away more heat with the help of the powerful heat exchange capacity of the liquid medium. These combinations give full play to their respective advantages and achieve more efficient and reliable heat dissipation effects.

In general, aluminum nitride substrate has great potential in improving the heat dissipation performance of electronic devices with its excellent thermal conductivity, mechanical strength and design flexibility. It can not only effectively reduce the operating temperature of electronic components and improve work efficiency, but also enhance the stability and durability of the system. With the advancement of technology and the growth of market demand, aluminum nitride substrate will be widely used in more fields and make greater contributions to promoting the innovative development of the electronics industry. In the future, we can expect to see more innovative designs based on aluminum nitride substrate, providing a more comprehensive and effective solution to the heat dissipation problem.