How does the high thermal conductivity of aluminum nitride substrates significantly improve the heat dissipation efficiency of high-power LED packages?

Release Time : 2025-10-09

With the rapid advancement of lighting technology toward higher brightness, higher integration, and longer lifespans, high-power LEDs are finding widespread application in urban lighting, automotive headlights, projection displays, industrial lighting, and other fields. If this heat cannot be dissipated promptly, it will cause the PN junction temperature to rise sharply, leading to accelerated light decay, color temperature drift, shortened lifespan, and even device failure. Therefore, efficient heat dissipation has become a core challenge in high-power LED packaging technology. Among various heat dissipation substrate materials, aluminum nitride substrates, with their superior thermal conductivity, are gradually replacing traditional aluminum oxide substrates as the preferred material for high-end LED packages.

1. High Thermal Conductivity: The Core Advantage of Aluminum Nitride

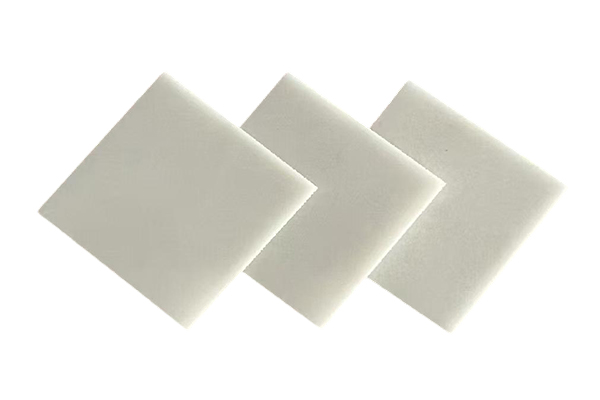

The thermal conductivity of aluminum nitride substrates is 6–9 times that of traditional alumina ceramic substrates, even approaching the thermal conductivity of metallic aluminum and significantly higher than other ceramic materials such as silicon nitride. This property enables them to quickly transfer heat generated by the LED chip from the junction area to the substrate base, where it is then dissipated to the ambient environment via a heat sink or heat spreader. In high-power LED packages, the chip is directly soldered or eutectic-bonded to the surface of an aluminum nitride substrate. Heat is conducted through the path from chip to solder layer to substrate to heat sink. Due to the extremely low thermal resistance of the aluminum nitride substrate, the temperature rise along the entire heat conduction path is significantly reduced, effectively controlling the LED junction temperature and ensuring stable operation within a safe temperature range.

2. Lowering Junction Temperature, Slowing Luminous Degradation, and Prolonging Lifespan

LED light output efficiency is negatively correlated with junction temperature. Experiments show that for every 10°C increase in junction temperature, the LED's luminous flux decay doubles, and its lifespan can be shortened by over 50%. Using an aluminum nitride substrate can reduce junction temperature by 15–30°C compared to using an alumina substrate. This means that under the same operating conditions, the LED's lumen decay is slower, color stability is improved, and lifespan is significantly extended. For example, in outdoor high-power floodlights or automotive headlights, the use of an aluminum nitride substrate enables LED modules to maintain high brightness output even in high-temperature environments, meeting stringent reliability requirements.

3. Supports High Power Density and Miniaturized Design

With the advancement of Mini/Micro LED and COB packaging technologies, LED chips are becoming increasingly densely integrated, leading to a dramatic increase in heat generation per unit area. Traditional substrates are no longer able to meet these heat dissipation requirements. The high thermal conductivity of aluminum nitride substrates enables efficient heat distribution and conduction within small, high-power density packaging structures, preventing the formation of localized "hot spots." This provides a physical foundation for miniaturized, lightweight, and high-brightness LED module designs. Designers can arrange more chips within a limited space, increasing luminous flux while maintaining excellent thermal management.

4. Excellent Electrical Insulation and Thermal Expansion Compatibility

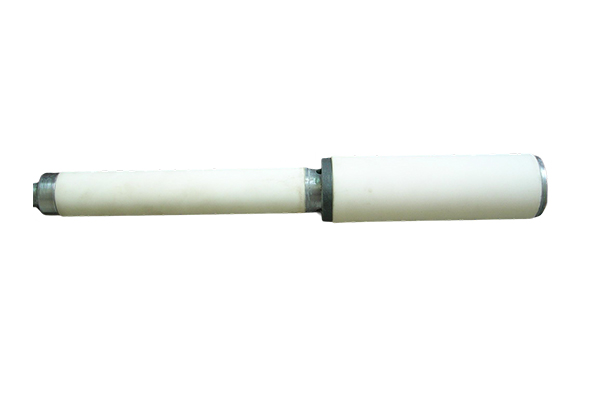

Aluminum nitride not only exhibits excellent thermal conductivity but also possesses good electrical insulation and a low dielectric constant, making it suitable for high-voltage and high-frequency operating environments. This excellent thermal compatibility reduces solder joint cracking, delamination, or chip breakage caused by uneven thermal stress during temperature cycling, significantly improving the mechanical reliability and long-term stability of the package structure.

5. Compatibility with Advanced Packaging Processes

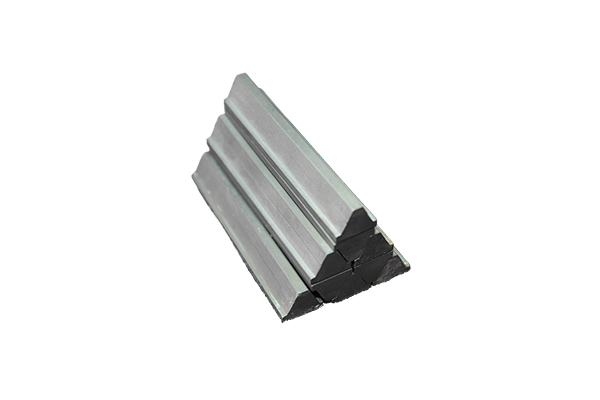

Aluminum nitride substrates enable highly reliable metallization through processes such as direct copper deposition and active metal brazing, creating fine circuit patterns that meet high-current transmission requirements. Their surfaces can be precision-polished to ensure excellent contact with the chip or heat sink, further reducing interfacial thermal resistance. In chip-on-board (COB) or surface-mounted device (SMD) packaging, aluminum nitride substrates provide an efficient heat dissipation platform for multi-chip integration, enabling higher power output.

In summary, aluminum nitride substrates, with their ultra-high thermal conductivity, play a key role as a "thermal highway" in high-power LED packaging. They not only significantly improve heat dissipation efficiency, lower junction temperature, slow lumen degradation, and extend lifetime, but also support high power density, miniaturization, and high-reliability designs. Although more expensive than traditional materials, their performance improvements and system-level reliability advantages make them an irreplaceable core material in high-end lighting, automotive electronics, and industrial applications.

1. High Thermal Conductivity: The Core Advantage of Aluminum Nitride

The thermal conductivity of aluminum nitride substrates is 6–9 times that of traditional alumina ceramic substrates, even approaching the thermal conductivity of metallic aluminum and significantly higher than other ceramic materials such as silicon nitride. This property enables them to quickly transfer heat generated by the LED chip from the junction area to the substrate base, where it is then dissipated to the ambient environment via a heat sink or heat spreader. In high-power LED packages, the chip is directly soldered or eutectic-bonded to the surface of an aluminum nitride substrate. Heat is conducted through the path from chip to solder layer to substrate to heat sink. Due to the extremely low thermal resistance of the aluminum nitride substrate, the temperature rise along the entire heat conduction path is significantly reduced, effectively controlling the LED junction temperature and ensuring stable operation within a safe temperature range.

2. Lowering Junction Temperature, Slowing Luminous Degradation, and Prolonging Lifespan

LED light output efficiency is negatively correlated with junction temperature. Experiments show that for every 10°C increase in junction temperature, the LED's luminous flux decay doubles, and its lifespan can be shortened by over 50%. Using an aluminum nitride substrate can reduce junction temperature by 15–30°C compared to using an alumina substrate. This means that under the same operating conditions, the LED's lumen decay is slower, color stability is improved, and lifespan is significantly extended. For example, in outdoor high-power floodlights or automotive headlights, the use of an aluminum nitride substrate enables LED modules to maintain high brightness output even in high-temperature environments, meeting stringent reliability requirements.

3. Supports High Power Density and Miniaturized Design

With the advancement of Mini/Micro LED and COB packaging technologies, LED chips are becoming increasingly densely integrated, leading to a dramatic increase in heat generation per unit area. Traditional substrates are no longer able to meet these heat dissipation requirements. The high thermal conductivity of aluminum nitride substrates enables efficient heat distribution and conduction within small, high-power density packaging structures, preventing the formation of localized "hot spots." This provides a physical foundation for miniaturized, lightweight, and high-brightness LED module designs. Designers can arrange more chips within a limited space, increasing luminous flux while maintaining excellent thermal management.

4. Excellent Electrical Insulation and Thermal Expansion Compatibility

Aluminum nitride not only exhibits excellent thermal conductivity but also possesses good electrical insulation and a low dielectric constant, making it suitable for high-voltage and high-frequency operating environments. This excellent thermal compatibility reduces solder joint cracking, delamination, or chip breakage caused by uneven thermal stress during temperature cycling, significantly improving the mechanical reliability and long-term stability of the package structure.

5. Compatibility with Advanced Packaging Processes

Aluminum nitride substrates enable highly reliable metallization through processes such as direct copper deposition and active metal brazing, creating fine circuit patterns that meet high-current transmission requirements. Their surfaces can be precision-polished to ensure excellent contact with the chip or heat sink, further reducing interfacial thermal resistance. In chip-on-board (COB) or surface-mounted device (SMD) packaging, aluminum nitride substrates provide an efficient heat dissipation platform for multi-chip integration, enabling higher power output.

In summary, aluminum nitride substrates, with their ultra-high thermal conductivity, play a key role as a "thermal highway" in high-power LED packaging. They not only significantly improve heat dissipation efficiency, lower junction temperature, slow lumen degradation, and extend lifetime, but also support high power density, miniaturization, and high-reliability designs. Although more expensive than traditional materials, their performance improvements and system-level reliability advantages make them an irreplaceable core material in high-end lighting, automotive electronics, and industrial applications.