How do aluminum nitride substrates perfectly match the demanding requirements of wafer-level packaging and flip-chip bonding?

Release Time : 2025-09-08

As semiconductor manufacturing progresses toward smaller, faster, and more powerful devices, wafer-level packaging and flip-chip bonding have become critical pathways for improving integration density and electrical performance. However, these advanced processes place extremely stringent demands on the substrate material—the "foundation" that supports the chips: it must conduct heat like wind and insulate like rock; it must be dimensionally stable like a rock and have a surface as smooth as a mirror; it must withstand both intense heat and microscopic stresses. Among the many candidate materials, aluminum nitride substrate, with its inherent physical properties and meticulously crafted process compatibility, has quietly become the most tacit partner in this delicate dance, perfectly meeting the rigorous demands of wafer-level packaging and flip-chip bonding.

Its suitability stems primarily from its dual harmony of thermal and mechanical properties. Wafer-level packaging strives for high microscopic conformity between the chip and substrate. Any deformation or misalignment caused by temperature fluctuations can lead to solder joint fracture or signal distortion. The aluminum nitride substrate has a thermal expansion coefficient very close to that of the silicon chip. When the package undergoes alternating cycles of cooling and heating in the high-temperature reflow oven, the substrate and chip, like a symbiotic organism, expand and contract in unison, minimizing interfacial stress and protecting the fragile electrical connection. This "resonant" harmony is a unique gift that traditional ceramics like alumina cannot achieve, and a shortcoming that metal substrates, due to their significant thermal expansion disparity, cannot match.

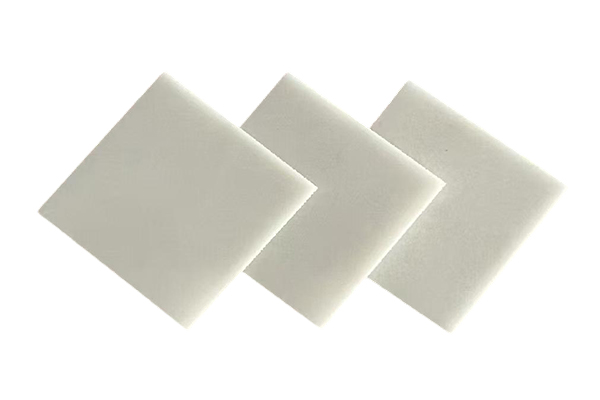

Ultimate surface flatness and microscopic cleanliness are the lifeblood of the flip-chip bonding process. Flip-chip bonding relies on the precise alignment and reliable bonding of the densely packed microbumps on the chip's underside with the substrate pads. The extremely small spacing and sheer number of these bumps mean no room for even the slightest fluctuation or contamination. The aluminum nitride substrate is precision ground and polished to a surface as smooth as a still lake, with a roughness level imperceptible to both the naked eye and instruments. It absorbs no moisture, produces no dust, and emits no organic volatiles, maintaining its virginity in cleanroom environments, ensuring every solder ball is securely seated and every solder joint firmly established. This unwavering pursuit of "absolute flatness" enables high-density interconnects and allows signals to flow unimpeded through nanoscale channels.

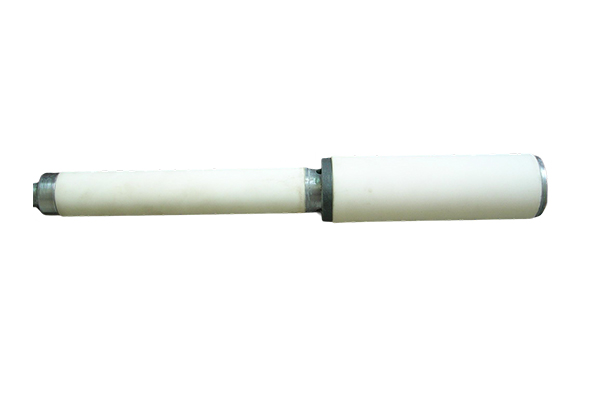

The purity of its electrical performance is also the secret weapon that allows aluminum nitride to conquer the world of high frequencies and high speeds. In the complex circuit networks constructed by wafer-level packaging, the substrate serves not only as a physical support but also as an invisible highway for signal transmission. Aluminum nitride possesses extremely low dielectric constant and dielectric loss, creating a dedicated, low-impedance, low-attenuation expressway for high-frequency signals. It resists drag, interference, and absorption, allowing signals at GHz and even THz levels to be transmitted with unwavering fidelity, unleashing the chip's immense computing power without loss. In cutting-edge fields such as 5G communications, AI accelerator cards, and high-speed optical modules, this characteristic has become the cornerstone for breaking through system performance bottlenecks.

Even more remarkable is its composure in extreme environments. Wafer-level packaging and flip-chip bonding processes often face the multiple challenges of high temperature, high humidity, and high voltage. Substrates must maintain structural integrity and stable performance despite these harsh conditions. Aluminum nitride ceramics possess inherently excellent chemical inertness, resisting acid and alkali corrosion and moisture penetration. Even in humid, muggy conditions or extreme temperature fluctuations, they maintain rock-solid insulation and unimpeded thermal conductivity. Unlike organic substrates, which are susceptible to aging and yellowing, or some metal substrates, which are susceptible to oxidation and corrosion, their near-permanent stability provides reliable protection for the package throughout the product lifecycle.

Finally, their adaptability is also reflected in their flexible and tolerant process compatibility. Whether sputtering, electroplating, photolithography, or laser drilling, aluminum nitride substrates seamlessly integrate with mainstream semiconductor manufacturing equipment and processes. Their surface is easily metallized, forming a highly adherent and conductive copper or gold layer, providing an ideal pad foundation for flip-chip bonding. Its rigidity is sufficient to support the precise alignment and press-fitting of wafer-level packaging, while its thermal conductivity quickly dissipates localized heat during the bonding process, preventing thermal damage. It doesn't dominate or create obstacles, but rather silently adapts itself to embrace, adapt, and achieve more advanced packaging forms.

For wafer-level packaging and flip-chip bonding, the aluminum nitride substrate is not a passive carrier but an active enabler. With its thermal harmony, surface perfection, electrical purity, environmental toughness, and process compatibility, it creates a sophisticated microcosmic stage, allowing chips to unleash their potential in the most ideal environment and continuously pushing the performance boundaries of electronic systems. In today's rapidly advancing semiconductor technology, it is not just a material, but a cornerstone; not just a choice, but a necessity.

Its suitability stems primarily from its dual harmony of thermal and mechanical properties. Wafer-level packaging strives for high microscopic conformity between the chip and substrate. Any deformation or misalignment caused by temperature fluctuations can lead to solder joint fracture or signal distortion. The aluminum nitride substrate has a thermal expansion coefficient very close to that of the silicon chip. When the package undergoes alternating cycles of cooling and heating in the high-temperature reflow oven, the substrate and chip, like a symbiotic organism, expand and contract in unison, minimizing interfacial stress and protecting the fragile electrical connection. This "resonant" harmony is a unique gift that traditional ceramics like alumina cannot achieve, and a shortcoming that metal substrates, due to their significant thermal expansion disparity, cannot match.

Ultimate surface flatness and microscopic cleanliness are the lifeblood of the flip-chip bonding process. Flip-chip bonding relies on the precise alignment and reliable bonding of the densely packed microbumps on the chip's underside with the substrate pads. The extremely small spacing and sheer number of these bumps mean no room for even the slightest fluctuation or contamination. The aluminum nitride substrate is precision ground and polished to a surface as smooth as a still lake, with a roughness level imperceptible to both the naked eye and instruments. It absorbs no moisture, produces no dust, and emits no organic volatiles, maintaining its virginity in cleanroom environments, ensuring every solder ball is securely seated and every solder joint firmly established. This unwavering pursuit of "absolute flatness" enables high-density interconnects and allows signals to flow unimpeded through nanoscale channels.

The purity of its electrical performance is also the secret weapon that allows aluminum nitride to conquer the world of high frequencies and high speeds. In the complex circuit networks constructed by wafer-level packaging, the substrate serves not only as a physical support but also as an invisible highway for signal transmission. Aluminum nitride possesses extremely low dielectric constant and dielectric loss, creating a dedicated, low-impedance, low-attenuation expressway for high-frequency signals. It resists drag, interference, and absorption, allowing signals at GHz and even THz levels to be transmitted with unwavering fidelity, unleashing the chip's immense computing power without loss. In cutting-edge fields such as 5G communications, AI accelerator cards, and high-speed optical modules, this characteristic has become the cornerstone for breaking through system performance bottlenecks.

Even more remarkable is its composure in extreme environments. Wafer-level packaging and flip-chip bonding processes often face the multiple challenges of high temperature, high humidity, and high voltage. Substrates must maintain structural integrity and stable performance despite these harsh conditions. Aluminum nitride ceramics possess inherently excellent chemical inertness, resisting acid and alkali corrosion and moisture penetration. Even in humid, muggy conditions or extreme temperature fluctuations, they maintain rock-solid insulation and unimpeded thermal conductivity. Unlike organic substrates, which are susceptible to aging and yellowing, or some metal substrates, which are susceptible to oxidation and corrosion, their near-permanent stability provides reliable protection for the package throughout the product lifecycle.

Finally, their adaptability is also reflected in their flexible and tolerant process compatibility. Whether sputtering, electroplating, photolithography, or laser drilling, aluminum nitride substrates seamlessly integrate with mainstream semiconductor manufacturing equipment and processes. Their surface is easily metallized, forming a highly adherent and conductive copper or gold layer, providing an ideal pad foundation for flip-chip bonding. Its rigidity is sufficient to support the precise alignment and press-fitting of wafer-level packaging, while its thermal conductivity quickly dissipates localized heat during the bonding process, preventing thermal damage. It doesn't dominate or create obstacles, but rather silently adapts itself to embrace, adapt, and achieve more advanced packaging forms.

For wafer-level packaging and flip-chip bonding, the aluminum nitride substrate is not a passive carrier but an active enabler. With its thermal harmony, surface perfection, electrical purity, environmental toughness, and process compatibility, it creates a sophisticated microcosmic stage, allowing chips to unleash their potential in the most ideal environment and continuously pushing the performance boundaries of electronic systems. In today's rapidly advancing semiconductor technology, it is not just a material, but a cornerstone; not just a choice, but a necessity.