How do precision ceramic screws maintain structural stability and corrosion resistance in extreme chemical environments? What specific industrial fields are they suitable for?

Release Time : 2025-08-11

In modern precision manufacturing, screws are the most fundamental and smallest connecting components. Innovations in their performance and materials often trigger chain reactions throughout the industry. When traditional metal screws face bottlenecks such as insulation failure, corrosion loss, or softening under high temperatures in extreme environments, a new solution emerges: precision ceramic-based screws. Precision screws not only push the boundaries of materials science but also redefine the meaning of "fasteners" with their superior insulation, corrosion resistance, and high-temperature resistance, becoming a key support for cutting-edge fields such as high-end electronics, aerospace, medical equipment, and new energy.

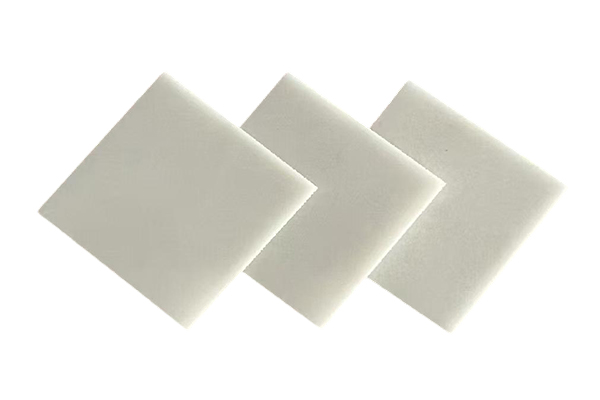

Aesthetics, in precision screws, are embodied in a tranquil texture and technological aesthetic that transcends metallic luster. Unlike the cold, reflective nature of metal screws, ceramics exhibit a matte finish that is as smooth as jade, with a pure and uniform color. Available in white, black, or custom colors, they meet the stringent aesthetic requirements of high-end equipment. Their surface is as smooth as a mirror, free of burrs and pores. Each screw undergoes nano-level polishing and precision sintering, exhibiting near-perfect geometric precision. Under a microscope, their dense and orderly grain structure resembles a miniature work of art. This restrained yet sophisticated visual language elevates them beyond just a functional component to become a hidden and elegant feature within precision instruments, highlighting their commitment to exquisite craftsmanship.

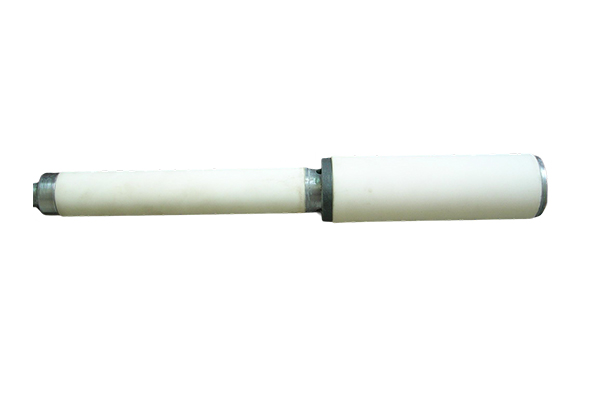

The core of precision screw innovation lies first and foremost in revolutionary breakthroughs in the materials themselves. Ceramic substrate materials, such as alumina (Al₂O₃), silicon nitride (Si₃N₄), or silicon carbide (SiC), inherently possess physical and chemical properties unmatched by metals. Their exceptional insulation properties make them ideal connectors for high-voltage, high-frequency electronic equipment, effectively preventing current leakage and signal interference, ensuring stable circuit operation. In high-temperature environments, ceramic screws can withstand extreme temperatures exceeding 1000°C without deformation or performance degradation, far exceeding the heat resistance limits of ordinary metal screws and providing reliable support for applications such as aerospace engines and high-temperature furnaces. Furthermore, its exceptional corrosion resistance ensures it remains stable in environments with strong acids, bases, or high humidity, preventing rust or degradation. This makes it particularly suitable for applications requiring the utmost in material purity, such as chemical equipment, marine engineering, and implantable medical devices.

At a deeper level, innovation lies in its core service model of "customization." The application scenarios for non-metallic materials vary widely, with unique requirements for screw size, thread specifications, head shape, mechanical strength, and even dielectric constant. The ability to customize precision ceramic screws means manufacturers possess a comprehensive technology chain, from material formulation design and precision mold development to high-temperature sintering and post-processing. They can precisely adjust the ceramic composition and optimize the sintering process to meet specific customer requirements, producing customized products that perfectly match their needs. This on-demand customization transforms screws from standardized "general-purpose parts" into highly specialized "solutions," addressing the pain point of customers facing a lack of suitable fasteners in extreme environments.

Ultimately, the value of precision screws lies in their ability to achieve absolute reliability in the harshest environments, using seemingly fragile materials. It's light yet tough, insulating yet conducting heat, resistant to high temperatures yet dimensionally stable. It's not just a bridge connecting two components; it's the cornerstone ensuring the safe, stable, and efficient operation of the entire system. Behind each tiny ceramic screw lies a perfect fusion of materials science, precision manufacturing, and deeply customized services. It proves that even the most basic industrial components can achieve a qualitative leap through innovation, becoming an invisible force driving technological progress. The moment it's precisely screwed into a high-end device, it silently guards every precise calculation, every life-saving operation, and every space exploration.

Aesthetics, in precision screws, are embodied in a tranquil texture and technological aesthetic that transcends metallic luster. Unlike the cold, reflective nature of metal screws, ceramics exhibit a matte finish that is as smooth as jade, with a pure and uniform color. Available in white, black, or custom colors, they meet the stringent aesthetic requirements of high-end equipment. Their surface is as smooth as a mirror, free of burrs and pores. Each screw undergoes nano-level polishing and precision sintering, exhibiting near-perfect geometric precision. Under a microscope, their dense and orderly grain structure resembles a miniature work of art. This restrained yet sophisticated visual language elevates them beyond just a functional component to become a hidden and elegant feature within precision instruments, highlighting their commitment to exquisite craftsmanship.

The core of precision screw innovation lies first and foremost in revolutionary breakthroughs in the materials themselves. Ceramic substrate materials, such as alumina (Al₂O₃), silicon nitride (Si₃N₄), or silicon carbide (SiC), inherently possess physical and chemical properties unmatched by metals. Their exceptional insulation properties make them ideal connectors for high-voltage, high-frequency electronic equipment, effectively preventing current leakage and signal interference, ensuring stable circuit operation. In high-temperature environments, ceramic screws can withstand extreme temperatures exceeding 1000°C without deformation or performance degradation, far exceeding the heat resistance limits of ordinary metal screws and providing reliable support for applications such as aerospace engines and high-temperature furnaces. Furthermore, its exceptional corrosion resistance ensures it remains stable in environments with strong acids, bases, or high humidity, preventing rust or degradation. This makes it particularly suitable for applications requiring the utmost in material purity, such as chemical equipment, marine engineering, and implantable medical devices.

At a deeper level, innovation lies in its core service model of "customization." The application scenarios for non-metallic materials vary widely, with unique requirements for screw size, thread specifications, head shape, mechanical strength, and even dielectric constant. The ability to customize precision ceramic screws means manufacturers possess a comprehensive technology chain, from material formulation design and precision mold development to high-temperature sintering and post-processing. They can precisely adjust the ceramic composition and optimize the sintering process to meet specific customer requirements, producing customized products that perfectly match their needs. This on-demand customization transforms screws from standardized "general-purpose parts" into highly specialized "solutions," addressing the pain point of customers facing a lack of suitable fasteners in extreme environments.

Ultimately, the value of precision screws lies in their ability to achieve absolute reliability in the harshest environments, using seemingly fragile materials. It's light yet tough, insulating yet conducting heat, resistant to high temperatures yet dimensionally stable. It's not just a bridge connecting two components; it's the cornerstone ensuring the safe, stable, and efficient operation of the entire system. Behind each tiny ceramic screw lies a perfect fusion of materials science, precision manufacturing, and deeply customized services. It proves that even the most basic industrial components can achieve a qualitative leap through innovation, becoming an invisible force driving technological progress. The moment it's precisely screwed into a high-end device, it silently guards every precise calculation, every life-saving operation, and every space exploration.